Time, tools, and cost estimates to complete each chapter in the book. These are only estimates as your tool availability and skill level may vary.

Note that this breakdown is for the 30 x 27 Build size. For a cost estimate for each build size go to the bottom of the page.

Chapter 1: Getting Started

Cost Estimate: $0

Time Estimate: None

Tools Needed:

- None

Chapter 2: Y-beam Assembly

Cost Estimate: $419

Time Estimate: Weekend

Tools Needed:

- 1/2" Wrenches

- Drill Press

- 1/8" Drill Bit

- 3/8" Drill Bit

Chapter 3: Table Construction

Cost Estimate: $609

Time Estimate: Weekend

Tools Needed:

- 7/16" Socket

- 1/2" Socket or wrench

- Framing square

- Dry wall square

Chapter 4: Y-carriage and Rail Construction

Cost Estimate: $326

Time Estimate: 3 Days

Tools Needed:

- 2, 1/2" Wrench's or sockets

- 2, 9/16" Wrenches

- Drill press

- 1/8" Drill bit

- 3/8" Drill bit

- 7/16" Drill bit

- 1/8" Allen wrench

Chapter 5: X-beam Construction

Cost Estimate: $234

Time Estimate: Weekend

Tools Needed:

- 1/2" Wrench

- Drill Press

- 1/8" Drill bit

- 3/8" Drill bit

Chapter 6: X-carriage Construction

Cost Estimate: $137

Time Estimate: One day

Tools Needed:

- 1/2" Wrench

- 9/16" Wrench

- 13mm Wrench

Chapter 7: Z-carriage Assembly

Cost Estimate: $300

Time Estimate: Weekend

Tools Needed:

- 7/16", 1/2", 9/16" Wrenches

- Drill press

- 1/8" Drill bit

- 3/8" Drill bit

- 5/64", 3/32", 1/8", 9/64" Allen wrenches

- Framing square

Chapter 8: Rack and Pinion Drives

Cost Estimate: $593

Time Estimate: One day

Tools Needed:

- 1/2" Wrench

- 9/16" Wrench

- 1/4" Allen wrench

- Reciprocating saw

Chapter 9: KRMx02 Electronics

Cost Estimate: $462

Time Estimate: One day

Tools Needed:

- Phillips screwdriver

- 5/16" Drill bit

- Portable drill or drill press

- Wire cutters

- Wire stripers

Chapter 10: Mach 3

Cost Estimate: $12

Time Estimate: Half day

Tools Needed:

- None

Chapter 11: Cable Hookup

Cost Estimate: $75

Time Estimate: Half day

Tools Needed:

- None

Chapter 12: Basic Tests

Cost Estimate: $0

Time Estimate: One Hour

Tools Needed:

- None

Chapter 13: Router Hookup

Cost Estimate: $190

Time Estimate: Two hours

Tools Needed:

- Phillips screwdriver

- 3/8" Wrench

- 3/16" Allen wrench

Chapter 14: Fences

Cost Estimate: $20

Time Estimate: Couple hours

Tools Needed:

- Drill press

- 1/2" Drill bit

- 1-1/2" Forstner bit

- Framing square

Chapter 15: Basic Operation

Cost Estimate: $226

Time Estimate: Couple hours

Tools Needed:

- 1/4 Spiral router bit (see text)

- 3/8" Drill bit

- Drill press

- Rotary grinder

- Saw used to cut stock and waster board (table saw, chop saw, band saw)

Chapter 16: Conclusion

Cost Estimate: None

Time Estimate: None

Tools Needed:

- None

Build Sizes and Costs

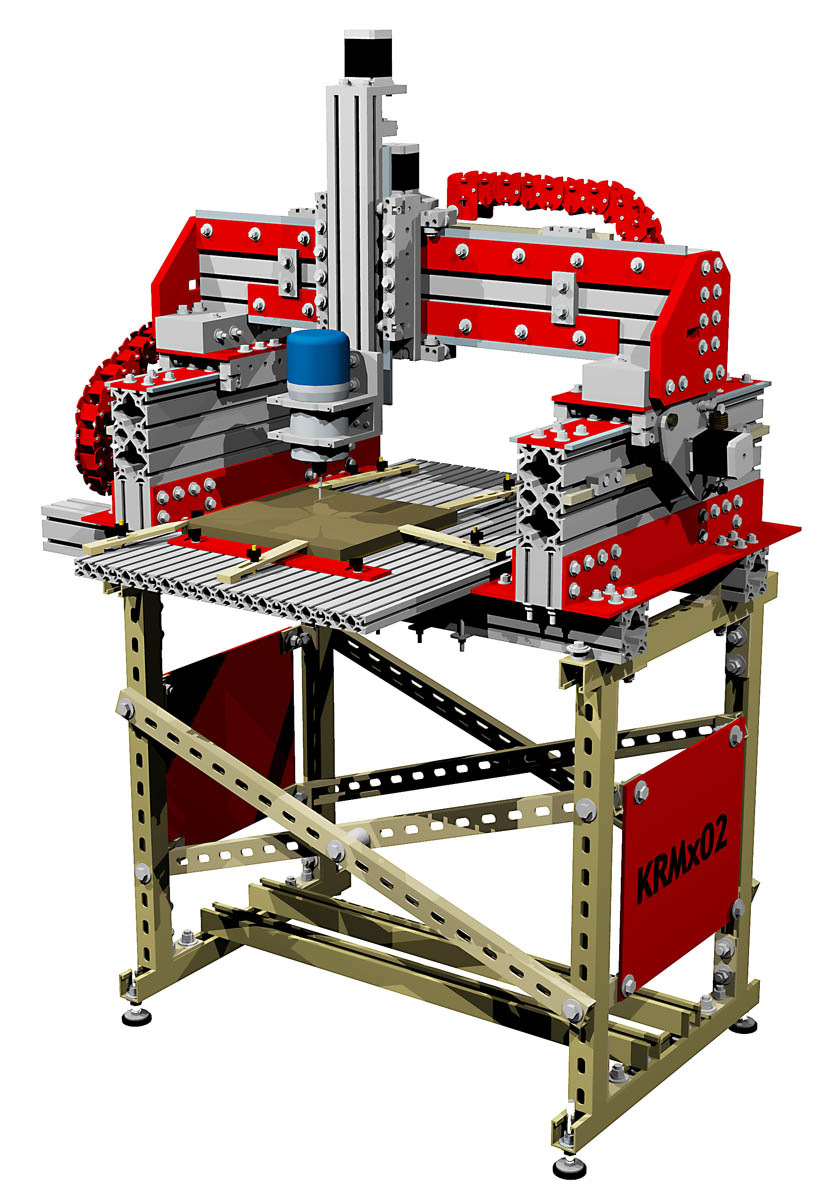

The KRMx02 was designed so that it can be built to any size. We supply a "Bill of Materials" for the following sizes.

Please be advised that the 18" x 14" and 30" x 27" machine sizes can be built by a single individual. The larger machines will require two or more individuals to aid in the assembly. Please note that the 50" gantry with the Z axis installed weighs about 250lbs.

When deciding on a machine size to build keep in mind that the build sizes given are the cutting sizes. The actual machine footprint will be larger.

18" x 14"

Cost Estimate: $2800

This is the machine we take to shows for demos. Of the three machines in the lab this little beauty is a favorite. Ours is mounted on 5" castors.

30" x 27"

Cost Estimate: $3500

This is the base build described in the book. The other sizes all require changes to the lengths of certain components. These are listed in the forums. If you have limited space this may be the machine for you.

50" x 27"

Cost Estimate: $3900

This is the base build with the X axis constructed to 50". This is good starting point, as the Y axis can be easy lengthened to 50" or 96" later with no change to the gantry. The cost estimate to build this CNC is $3900.

50" x 50"

Cost Estimate: $4630

This is the most popular build size. It is large enough to support most projects, yet will still fit in most shops.

50" x 102"

Cost Estimate: $5580

This is a monster. It utilizes the same gantry as the 50" x 27" and 50" x 50" so the need for larger electronics are not needed. The stand for this machine requires six support posts with leveling feet to properly support the machine.

The above costs do not include shipping charges, or taxes. It does include all electrics, router and controller software.

Parts Bundles

While there is not a complete kit available for the various build sizes. There are extensive parts bundles available from a couple vendors. The sources for these bundles as well as a bill of materials for each build size. The bill of materials includes sources, part numbers and in many cases direct links to the actual part or bundle.